Introduction:

Configurable materials is used to define products that have different variants

The usage of configurable materials Show clearly in some industries like Textile, carton. By using Configurable material you will have one material code with different specification for each sales order. Due that quality inspection of Configurable materials should be treated differently than standard product.

The issue:

Due to the different specification of the same Configurable material for each sales order. the tolerance of some inspection Characteristic should adapt with the specification of each sales order. For example Length, thickness and so on. And that tolerance will be transfer from sales order specifications

The solution:

I will mention the required steps followed by an example

In order to use QM inspection with configurable material Firstly you have to group the inspection characteristics into two groups

1- characteristics that will be added to inspection lot with the same tolerance regardless the configurable material specs

(These characteristics will be added direct in the inspection plan)

2- characteristics that will be added to inspection lot

Or it’s tolerance will change depend on the configurable material specs

For this type: we have to do as below :

- Maintain Modification required in Note 119708 then flow below steps

1 – Create Class characteristic and assign it to each inspection characteristic

(With the same type (Numeric/character) and length

2 – assign this Class characteristic into class 300

3 – Maintain selection condition dependency that determine in which condition we will call the inspection characteristic in the inspection lot

4 – for the quantitative inspection characteristics that we need to change its tolerance we can user variant table to trigger the values or just add the value manually during the sales order creation

5 – As per SAP note 119708 for the inspection characteristic That has interval (Tolerance from to) we will create two inspection characteristics one will hold the lower value and the other one will hold the upper value we will link the inspection characteristic with configuration characteristic that hold the lower value

6- In case of qualitative inspection characteristic we will use the value of

7 – For both Types (Qualitative & Quantitative) value must be existed during configuration to be appeared in inspection lot

An Example :

Firstly maintain Modification of Note 119708 Then

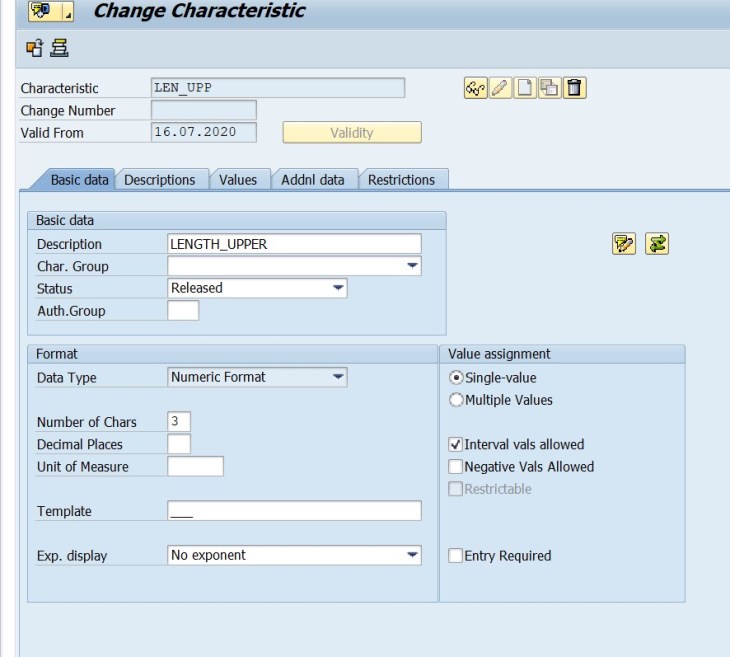

1 – Create class characteristics for lower and upper values : CT04

2 – Create inspection characteristic . with link to lower Class characteristic

3 – Create Inspection Plan . that contains only the inspection characteristics that will be appeared in

inspection lot regardless the specification of the configurable material

4 – Maintain Value in table ZQMCF

5 – Maintain the check mark of Inspection by configuration as below

6 – Create sales order and assign value for Lower and Upper characteristics in configuration

– The value of Lower and Upper characteristics will be transferred to the Inspection characteristic Length

7 – Convert planned order to production order and maintain GR

8 – Result Recording QA32

– As you see the tolerance of inspection characteristic (Length) become 20 – 27. Transferred from the Variant characteristics (LEN_LOW / LEN_UPP)